Home / Tips and Trends / Production

This section covers the following major heads. Click on the links below to directly go to the related topic or simply scroll down to read all of them

Capacity enhancement refers to enhancing an individual’s, group’s or organisation’s ability to work towards its mission which may be made possible by providing training and development sessions, providing coaching, supporting collaboration with others and the like.

The UN Development Program defines “capacity” as “the ability of individuals, institutions and societies to perform functions, solve problems, and set and achieve objectives in a sustainable manner”. The terms “capacity building” or “capacity development” describe the task of establishing human and institutional capacity.

1. The country’s resources and capabilities 2.An enabling institutional environment

As per Wikipedia, Cost leadership is a way to establish the competitive advantage. Cost leadership, in basic words, means the lowest cost of operation in the industry. The cost leadership is often driven by company efficiency, size, scale, scope and cumulative experience (learning curve). A cost leadership strategy aims to exploit scale of production, well defined scope and other economies (e.g. a good purchasing approach), producing highly standardized products, using high technology, reducing waste & optimizing use of resources. In the last years, more and more companies choose a strategic mix to achieve market leadership. These patterns consist in simultaneous cost leadership, superior customer service and product leadership.

Cost leadership is different from price leadership. A company could be the lowest cost producer, yet not offer the lowest-priced products or services. If so, that company would have a higher than average profitability. However, cost leader companies do compete on price and are very effective at such a form of competition, having a low cost structure and management.

Quality control is a process employed to ensure a certain level of quality in a product or service. It may include whatever actions a business deems necessary to provide for the control and verification of certain characteristics of a product or service. The basic goal of quality control is to ensure that the products, services, or processes provided meet specific requirements and are dependable, satisfactory, and fiscally sound.

Essentially, quality control involves the examination of a product, service, or process for certain minimum levels of quality.

Quality control is concerned with checking and reviewing work that has been done or is under process. Under quality control, inspection of products and services (checking to make sure that what’s being produced is meeting the required standard) takes place during and at the end of the operation process.

In case, some non-conformity is observed in the product design or quality, inform and consult your customer (prior to dispatching the goods). Sometimes the customer can still accept the lot. Sometimes, offering a reasonable discount for small defects can also help. But remember these are remote possibilities and these may or may not materialize. Also, such conditions should not be made a practice but only once in a while.

As per Wikipedia, like human beings, products also have their own life-cycle. From birth to death, human beings pass through various stages e.g. birth, growth, maturity, decline and death. A similar life-cycle is seen in the case of products. The product life cycle goes through multiple phases, involves many professional disciplines, and requires many skills, tools and processes. In simple words, the stages through which individual products develop over time is commonly known as the “Product Life Cycle”.Product life cycle (PLC) has to do with the life of a product in the market with respect to business/commercial costs and sales measures. To say that a product has a life cycle is to assert four things:

We define a product as “anything that is capable of satisfying customer needs”. This definition includes both physical products (e.g. cars, washing machines, DVD players) as well as services (e.g. insurance, banking, private health care).

Businesses should manage their products carefully over time to ensure that they deliver products that continue to meet customer wants. The process of managing groups of brands and product lines is called portfolio planning.

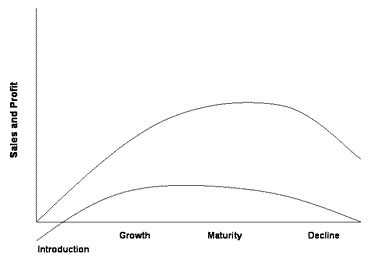

The classic product life cycle has four stages (illustrated in the diagram below): introduction; growth; maturity and decline

At the Introduction (or development) stage, market size and growth is slight. It is possible that substantial research and development costs have been incurred in getting the product to this stage. In addition, marketing costs may be high in order to test the market, undergo launch promotion and set up distribution channels. It is highly unlikely that companies will make profits on products at the Introduction Stage. Products at this stage have to be carefully monitored to ensure that they start to grow. Otherwise, the best option may be to withdraw or end the product.

The Growth Stage is characterised by rapid growth in sales and profits. Profits arise due to an increase in output (economies of scale) and possibly better prices. At this stage, it is cheaper for businesses to invest in increasing their market share as well as enjoying the overall growth of the market. Accordingly, significant promotional resources are traditionally invested in products that are firmly in the Growth Stage.

The Maturity Stage is, perhaps, the most common stage for all markets. It is in this stage that competition is most intense as companies fight to maintain their market share. Here, both marketing and finance become key activities. Marketing spend has to be monitored carefully, since any significant moves are likely to be copied by competitors. The Maturity Stage is the time when most profit is earned by the market as a whole. Any expenditure on research and development is likely to be restricted to product modification and improvement and perhaps to improve production efficiency and quality.

In the Decline Stage, the market is shrinking, reducing the overall amount of profit that can be shared amongst the remaining competitors. At this stage, great care has to be taken to manage the product carefully. It may be possible to take out some production cost, to transfer production to a cheaper facility, sell the product into other, cheaper markets. Care should be taken to control the amount of stocks of the product. Ultimately, depending on whether the product remains profitable, a company may decide to end the product.