Home / All Socio-economic Activities / New milestone for blue pottery artisans with advanced machinery…A capacity building initiative by SETU….

SETU is associated with a no. of pottery artisans, including terracotta & blue pottery. We have helped their crafts to reach international levels by capacity building, quality improvement, design & functionality upgradation, installation of upgraded machinery, integrating new technology, training workshops etc.

One of our blue pottery artisans is located in a small village near Jaipur. Pottery is their ancestral craft, passed down from generations. And hence a lot of machinery & technology available with them is outdated.

One such machinery was the Glaze making Kiln. The glaze making furnace typically consists of an insulated chamber or kiln, which is a high-temperature oven, capable of reaching temperatures required for various raw materials to melt and form a glassy mixture called glaze. The glaze needs to be properly fired, to achieve good vitrification. This process strengthens the pottery piece, enhances its appearance, and adds various decorative effects such as color, texture, and sheen.

The artisans had been using an old, mud coated dilapidated furnace, fired by traditional fuel such as coal. Design & insulation were improper, resulting in wastage of heat & extra fossil fuel consumption. Generation of black smoke & coal sparks posed health & environmental risks. The amount of glaze that could be prepared was too less compared to the fuel used. Excess time and manpower were consumed. The quality of glaze produced wasn’t satisfactory due to smoke particles & inadequate temperatures, resulting in poor quality of the final products. Thus health, safety, environment & savings all were getting compromised.

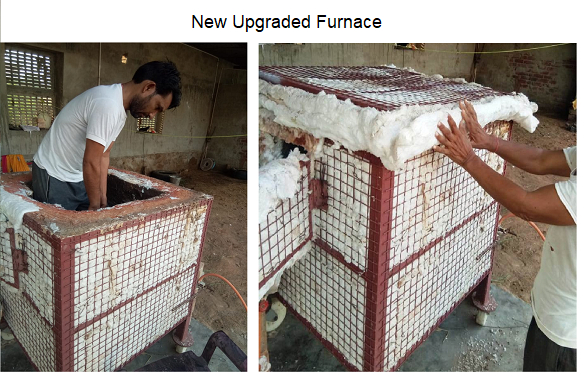

And so, SETU sponsored a new Glaze Kiln for the artisans. This is a robust kiln has a properly insulated heating container, with LPG as the firing medium instead of coal. The cost of heating is now much lesser. The overall time taken to fire the glaze is now only one third of the earlier. Also, there is no smoke, no undue heat losses and very less manpower requirement. The whole process is neat and methodical. The quality of glaze produced is clean and uniform, resulting in less rejections & good quality of products. Along with safeguarding of health & environment, there are multi-fold economic advantages.

Artisan health and safety are crucial for their well-being, productivity, development, and all-round sustainability. It ensures a safe working environment, enhances productivity, retains talent, builds customer confidence and determines social responsibility.